By continuing to browse our site, you agree to the storing of cookies on your device to help us understand your preferences and improve our services, ensuring that we can provide you with the best possible experience. To learn more, check out our Cookie Policy.

Infection Control > Rotary Sealer

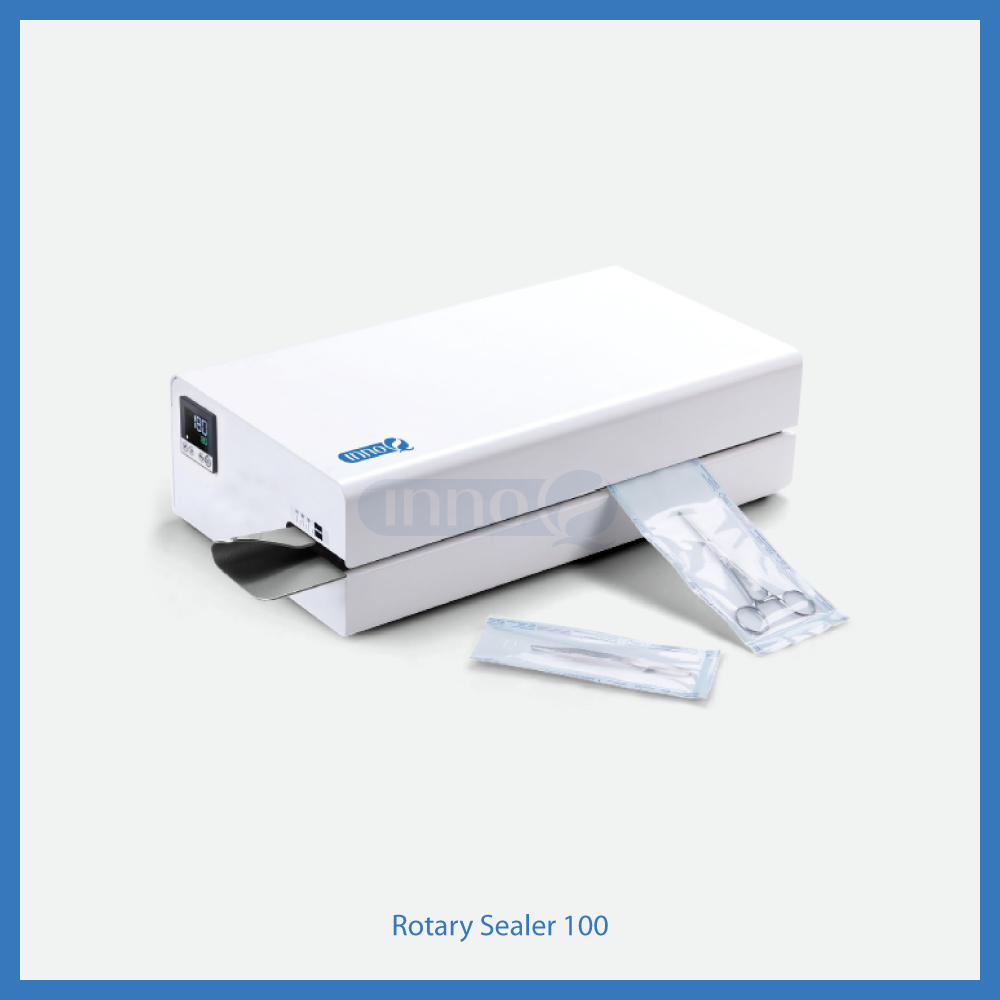

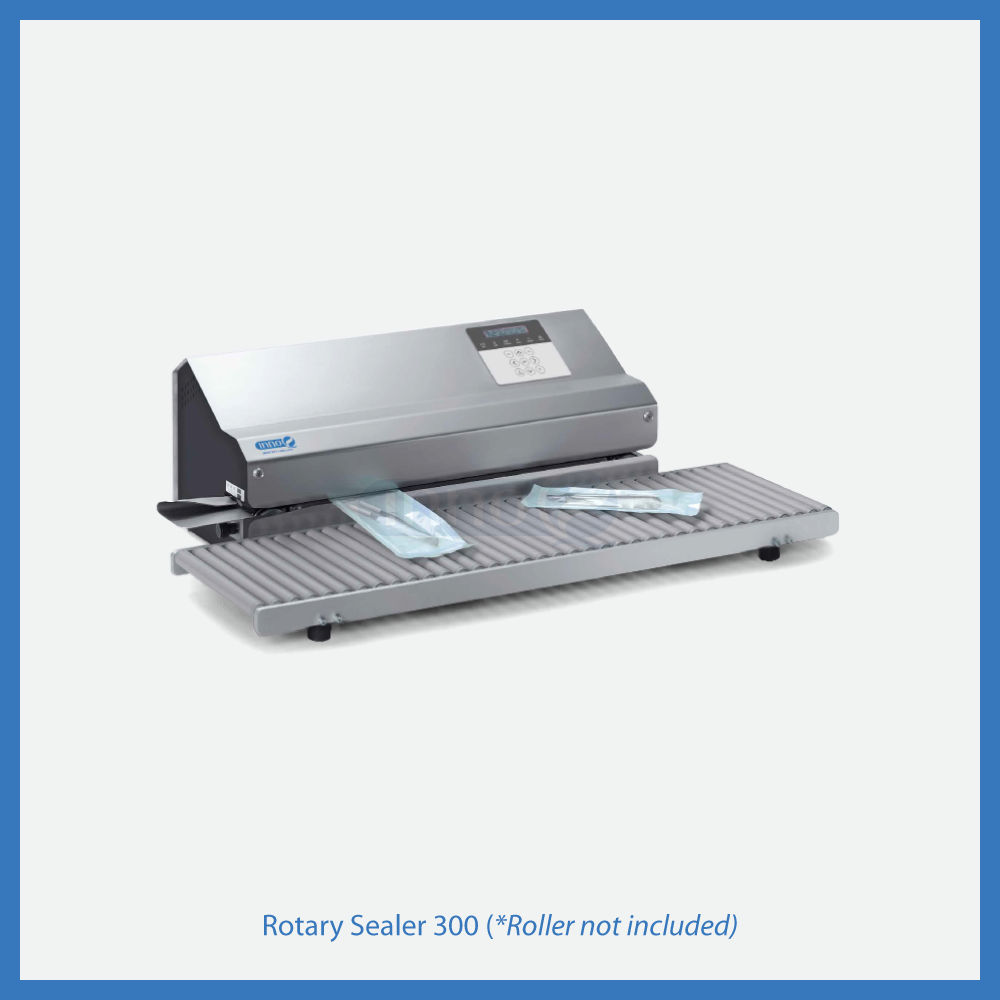

Rotary Sealer 100 & 200

Flexibility

- Suitable for packaging sealable paper bags (EN ISO 11607-1/EN 868-4) as well as sealable pouches and reels (EN ISO 11607-1/EN 868-5)

Operation

- Easy to operate via its intuitive temperature control and easy to clean through its new color coated surface

Safety

- Exact temperature control, constant contact pressure and sealing speed guarantee reproducible sealing results.

- Device switches off automatically if sealing temperature is out of tolerance (±5 °C according to DIN 58953-7)

Efficiency

- High sealing output can be achieved thanks to the band sealing process of 10 m/min (393 inch/min)

Seal Stability

- Sealing seams are 12 mm wide flat with a barrier and excellent stability in the center

- As seal stability increases constantly from the outside towards the center, the soft edges have the advantage that instruments do not break out at the edges

- Ideal even for uncoated Tyvek® and polyolefin packagings

Sustainability

- Power consumption of only 160 watts (may vary during heat up process) the sealers are a contemporary companion in the daily packaging routine

- A resource-efficient design, the sealers use new sealing technology that largely negates the need for PTFE wear parts and requires only a fraction of the energy of comparable devices

Additional Function - For Seal 200

Integrated Printer

-

Data such as name or ID of wrapper, expiry/sterilization date, LOT number, etc., can directly be printed on the porous part of the material (outside the heat seal line

| Product Code | Product Description | |

|---|---|---|

|

|

INQIFC101000 | InnoQ Seal 100 |

|

|

INQIFC101001 | InnoQ Seal 200 (with printer) |